Split bearings can be mounted conveniently and quickly without removing other components of the shafts. So the service cycle and maintenance cost are shortened to half. They have little working resistance and can running smoothly for the special design, and the working temperature would reach 180°C. Thus, they are extremely suitable for the applications with low speed, heavy loads or severe conditons.

Split bearings are often used in such applications as converter supportings, roll neck supportings of conticasters, large transportation equipment where the dismounting conditions are limited and difficult ro replace solid bearings.

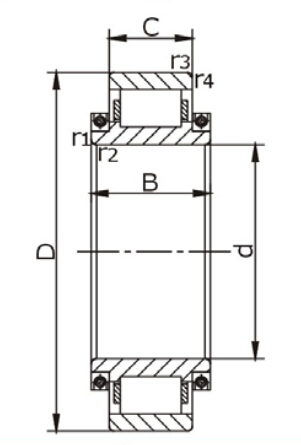

| Model | Boundary dimensions (mm) | Basic load ratings (KN) | Dimensions (mm) | Weight (KG) | |||||||

| d | D | B | C | rsmin | r1smin | dyc_Cr | stc_Cor | d1 | D1 | ||

| 803824 | 120 | 200 | 142 | 80 | 2 | 2 | 555 | 900 | 166 | 169 | 17 |

| 803928 | 140 | 230 | 102 | 53 | 2 | 2 | 370 | 600 | 180 | 190 | 14 |

| 803828 | 140 | 290 | 110 | 80 | 3 | 3 | 838 | 1145 | 193 | 247.5 | 31.2 |

| 803830X3 | 148 | 225 | 142 | 75 | 2.1 | 2.1 | 535 | 950 | 180 | 197 | 14 |

| 803836 | 180 | 300 | 125 | 74 | 2.1 | 2.1 | 715 | 1200 | 220 | 248 | 30 |

| 803856 | 280 | 500 | 260 | 176 | 5 | 5 | 2710 | 4650 | 419 | 439 | 175 |

| 803860 | 300 | 500 | 240 | 160 | 5 | 5 | 2527 | 4465 | 418 | 434 | 165 |

| 803864K | 320 | 540 | 250 | 176 | 6 | 6 | 2395 | 4586 | 439 | 454 | 196.5 |

| 803868 | 340 | 580 | 280 | 190 | 5 | 5 | 2930 | 5574 | 475 | 487 | 235 |

| 803872 | 360 | 540 | 220 | 134 | 5 | 5 | 2250 | 4500 | 476 | 482 | 155 |

| 803880 | 400 | 600 | 240 | 148 | 5 | 5 | 2880 | 5850 | 522 | 541 | 205 |

| 803884 | 420 | 620 | 238 | 150 | 6 | 6 | 2880 | 5850 | 542 | 562 | 215 |

| 803892 | 460 | 700 | 245 | 165 | 6 | 6 | 3280 | 6550 | 604 | 635 | 340 |

| 803894 | 470 | 720 | 270 | 167 | 6 | 6 | 3570 | 7500 | 646 | 656 | 375 |

| 8039/560 | 560 | 800 | 230 | 150 | 5 | 5 | 3340 | 8150 | 669 | 742 | 320 |

| 8038/560 | 560 | 870 | 330 | 200 | 6 | 6 | 5060 | 11000 | 733 | 786 | 580 |

| 8039/600 | 600 | 920 | 310 | 212 | 9.5 | 7.5 | 5640 | 12000 | 798 | 837 | 690 |

| 8038/600 | 600 | 980 | 515 | 375 | 7.5 | 7.5 | 10400 | 21600 | 811 | 833 | 1350 |

| 8038/630 | 630 | 920 | 310 | 212 | 16 | 7.5 | 5245 | 11390 | 800 | 825 | 628 |

| 8038/670 | 670 | 980 | 350 | 230 | 7.5 | 7.5 | 6440 | 14000 | 860 | 890 | 800 |

| 8039/710 | 710 | 950 | 375 | 243 | 6 | 6 | 5750 | 15300 | 860 | 868 | 700 |

| 8038/710 | 710 | 1030 | 360 | 236 | 7.5 | 7.5 | 7020 | 15600 | 901 | 939 | 880 |

| 8039/750 | 750 | 1000 | 360 | 250 | 6 | 6 | 6300 | 17000 | 900 | 916 | 710 |

| 8038/750 | 750 | 1090 | 340 | 250 | 8 | 8 | 6600 | 15330 | 950 | 980 | 932 |

| 8038/750X2 | 750 | 1090 | 475 | 335 | 7.5 | 7.5 | 9950 | 24000 | 938 | 969 | 1300 |

| 8039/800 | 800 | 1060 | 370 | 258 | 6 | 6 | 6900 | 18600 | 955 | 968 | 8100 |

| 8038/800 | 800 | 1150 | 450 | 345 | 16 | 8 | 10000 | 24800 | 1010 | 1018 | 1500 |

| 8037/850 | 850 | 1120 | 380 | 272 | 6 | 6 | 7360 | 2800 | 1008 | 1028 | 830 |

| 8039/1120 | 1120 | 1460 | 500 | 335 | 7.5 | 7.5 | 11500 | 33500 | 1330 | 1350 | 2070 |